Why Do Pilots Use Continuous on Engines

Aircraft are designed to fly. When they're going to spend more than 15 hours in the air, they need to perform as efficiently as possible. From getting the most power out of the engines to maximizing the lift from the wings, the main part of the design process is focused on the airborne aspect. However, it's no good creating the perfect flying machine if you can't get it to and from the terminal building. So, how do you get 200 tons of aircraft from the runway to the gate?

The Airport Set Up

Bigger Than Cities

Large international airports can be massive places. Denver, Colorado's main airport, for example, takes up an area of 53 square miles. By comparison, the area of Manhattan is 34 square miles, San Francisco is 47 square miles and Miami is 36 square miles. At some airports like Amsterdam, once you've landed you can still have several miles left to taxi until you reach the terminal building. Conversely, some busy airports are so restricted for space that it poses real issues for aircraft getting around on the ground. New York's JFK is a prime example of this.

Sign up for our daily newsletter

The area on which aircraft move on the airfield can broadly be separated into three separate categories. The ramp, or apron, is where the stands are located for aircraft to park. The runways are what the aircraft use to takeoff and land. And the taxiways, which they use to get between the two.

Stands, Taxiways and Runways

At most international airports, the runways are either 45 meters or 60 meters wide and can vary in length. London Heathrow has one of the longest runways in the UK at just under 4 kilometers, or around 2.5 miles. At around 380 tons on landing, runways have to be able to withstand repeated impact from aircraft such as the Airbus A380. They also need to ensure that water drains off quickly when it rains so that it doesn't become too slippery.

Taxiways, too, can vary in width and load-bearing strength depending on the airfield. Depending on these factors, they are categorized so that pilots know which taxiways they are able to use for their aircraft type. The taxiways at some airports can be particularly tight, especially for bigger aircraft. With a wingspan of more than 60 meters, pilots on the 787 Dreamliner always have to be mindful of their wingtips.

Parking stands can also vary in width and length, depending on the aircraft type they are to accommodate. It is on these stands where aircraft park and are unloaded and loaded between flights. They have to provide electrical power for the aircraft whilst the engines are shut down and also enough area around the aircraft to give the multitude of servicing vehicles space to access the aircraft. At some big airports, when not in use by a bigger aircraft, one stand can be used by two smaller aircraft.

How Aircraft Move

Most Aircraft Can't Reverse

When you arrive at the gate for your flight, more often than not you'll get a great view of the nose of the aircraft through the terminal window. If you look closely, you'll be able to see us pilots preparing the aircraft for departure. Funny enough, we can see you peering out at us too, so if we wave, don't be embarrassed to wave back.

However, the obvious problem with parking facing the terminal is that in order to get to the runway, we need to move backward off the stand first. If this was on your drive at home, you'd just pop your car into reverse, back out onto the street and off you go. Unfortunately, aircraft are unable to do this as they don't have a reverse gear. In order to get round this problem, we use the assistance of a pushback tug.

Pushback Tugs: The Little Engines That Could

For smaller aircraft, the pushback tug doesn't require a massive amount of power. They utilize the weight of the tug, sometimes up to 60 tons, to ensure that the wheels don't just spin on the tarmac. "The small ones have enough power to push and tow an aircraft up to a 757," says Airside MUC, a pushback driver at Munich International Airport. "The functionality is pretty simple. We connect a tow-bar at the aircraft first, then at the tug."

It takes skill to push an aircraft back using these types of tug. "You have two steering axis here at the nose gear and at the tug where the tow-bar is connected," he said. "So when you steer right, the nose of the aircraft goes opposite."

However, with bigger aircraft, tug designers ran into a problem. Even with a 60-ton tug, there isn't enough weight to stop the tug wheels spinning. To get round this problem, they needed something to weigh the tug down. Something like the weight of a 560-ton A380.

Tow-barless tugs clamp around the nose wheel of the aircraft and lift it up, thus utilizing the weight of the aircraft to provide the traction for its wheels. "We need between 40 and 90 seconds to connect the tug with the aircraft and lift it up," he added. "The Goldhofer AST-1X is the Godfather of all tugs because at 32 tons, its 16-liter 700 HP engine is enough to push all heavies easily. We use that tug for 767 up to A380."

Engines Provide the Thrust

Once the tug has disconnected and the engines are running, the pilots call ATC for their clearance to taxi to the departure runway. They will then be issued with a series of taxiways, which will eventually take them to the departure point. At smaller airports, this may just be one taxiway. At larger airfields it could be a number of taxiways, broken up into segments to give way to other aircraft. It's worth noting that aircraft don't 'taxi down the runway'. They taxi on taxiways, hence the name, taxiway. (Sometimes aircraft do have to taxi on the runway, but this is relatively infrequent. So, for the case of this article, I decided to keep it simple.)

If this was your car, you'd put the gear into drive or first gear and press the accelerator. This would inject fuel into the engine and provide power to turn the wheels and off you'd go. However, aircraft wheels aren't connected to the engines in any way. When the pilots squeeze the thrust levers forwards, the thrust generated from the engines pushes the aircraft forwards. The wheels merely turn under this forward power allowing the aircraft to move.

Steering System

Once moving, pilots need to be able to steer the aircraft around corners. With a wingspan of 60.1 meters, the 787-8 is wider than it is long. The pilot's eye level is 5.5 meters above the ground, and this creates a 14-meter blind spot ahead of the aircraft. So, accurate taxiing is essential.

This is done through two different sets of controls. Limited steering is possible using the rudder pedals, which sit underneath the pilot's feet. Unlike in your car, the pedals under our feet have very little to do with acceleration and a lot to do with braking and steering. These primarily control the rudder on the tail (mainly used in crosswind landings) and also control the brakes. However, the main source of steering comes from the nosewheel steering tiller, which can turn the nose wheel up to 70 degrees.

The Braking System

Brakes on the Main Wheels

Getting moving is no good unless you can bring the aircraft safely to a stop. To do this, each wheel on the main landing gear has a brake unit. On most aircraft, the brakes are powered by the hydraulics system. However, on the 787 Dreamliner, which I fly, the eight main wheel brakes are electrically powered instead. This means that the aircraft then produces fewer CO2 emissions due to the lower weight — 111 kilograms for each 787-9 aircraft. The simplified system also benefits engineers as the procedure to replace a brake unit is much quicker and easier.

Being such a safety critical part of the aircraft, the braking system has to work well under all conditions. This includes situations where a brake unit isn't working. During the testing stage of the aircraft, engineers put them through a punishing process as can be seen in the video below.

It's from this and further testing that it was determined that a Dreamliner could safely stop even with two of the eight braking units not working. The braking system also has two further features: Antiskid Protection and Autobrake. The autobrake system provides automatic braking at a deceleration rate selected by the pilots. For every landing, pilots calculate how much runway they will require depending on their weight and weather conditions. They can then select a level of autobrake to have them slowed safely to exit the runway. As soon as the aircraft touches down, the aircraft evenly applies the required braking pressure across all of the brakes. This results in smoother deceleration of the aircraft and makes it much more comfortable for passengers.

However, when landing at 190 tons on a slippery runway in the middle of winter, the last thing you want is for your wheels to start skidding. To protect against this, most airliners have an Antiskid Protection system. Each wheel has a wheel speed sensor, which, when it detects a skid, reduces the braking force until the skid is no longer detected. This ensures maximum braking efficiency is achieved, even in the most challenging of conditions.

Finding Your Way Around

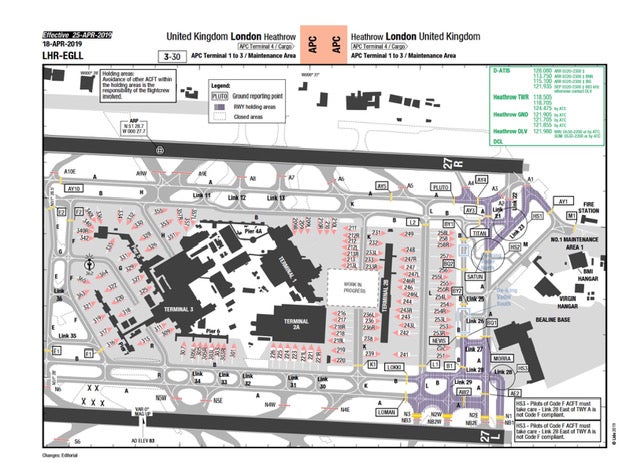

Getting around some airports can be quite challenging. Taxiways seem to go all over the place, with some ending in dead ends and others leading onto runways. As a result, pilots have to keep their wits about them. To help us, taxiways are given an alphanumeric name to help differentiate them from one another. These are then depicted on a map of the airport, which is provided to the pilots.

Modern aircraft have gone one better than a map and have a moving display — very much like the navigation system in your car. Pilots are able to see exactly where the aircraft is in relation to the runways and taxiways around it. This is particularly useful at night or when the weather is bad, giving pilots greater spatial awareness and reducing errors as a result.

Parking

You may have flown thousands of miles, but the last few meters of the flight can often be the most challenging. The parking stand is a super busy place, so the pilots need to ensure that they stop the aircraft in exactly the correct spot. Too short or too far and the air bridge may not reach the door. Too far left or right and they risk clipping the wingtip of the aircraft parked next door. When it comes to this level of precision, what better to trust than the accuracy of lasers.

Laser-Guided Docking Systems

At the front of each parking stand is a docking system. Using 3-D scanning techniques, the system cannot only recognize the type of aircraft, but also detect any obstructions on the stand. As the aircraft approaches the stand, the system provides the pilots with directions to keep them lined up with the center of the stand and also the distance left to the stop mark.

Should an obstruction, such as a rogue vehicle, be detected on the stand as the aircraft approaches, the display will issue the pilots with a command to stop. This is why it's important that you keep your seat belt fastened until the signs are turned off.

If you've watched any film with an aircraft in it, you've probably seen people waving at the pilots with what look like light sabers. This isn't them asking for a game but instead it's another way of guiding aircraft to their parking spot. The marshaller uses a combination of hand signals to communicate with the pilots to tell them to slow down, move left or right and to stop.

Bottom Line

Controlling an aircraft in the air is important, but being able to steer it accurately on the ground is equally so. Pilots rely on the skill of tug drivers to position the aircraft on the taxiway before heading to the runway. They then use a combination of controls to navigate around the complicated network of taxiways before getting airborne.

After landing, the flight still isn't over, as pinpoint parking is needed. Stray catering trucks and baggage carts can cause the aircraft to come to a sudden stop, so make sure you keep your seat belt fastened until the pilots turn off the signs.

Source: https://thepointsguy.com/guide/how-pilots-move-a-plane-around-on-the-ground/

Belum ada Komentar untuk "Why Do Pilots Use Continuous on Engines"

Posting Komentar